From plant to plane and waste to wingtip: What is sustainable aviation fuel?

January 22, 2024

Resources

In the pursuit of achieving more sustainable practices, the aviation industry is undergoing a transformative shift to reach net-zero carbon emissions by 2050. As a substantial contributor to greenhouse gas (GHG) emissions, the industry has been actively seeking alternatives to traditional jet fuel.

At the forefront of this search, sustainable aviation fuel (SAF) emerges as the most promising solution to decarbonization. This innovative fuel not only serves as an alternative but also reflects the conscientious steps being taken to mitigate climate change and the carbon footprint of air travel.

Understanding the complexities of SAF—from production and certification to procurement and usage, and its impact on reducing carbon emissions on a lifecycle basis—is vital for the industry to successfully coalesce around SAF as a solution and align on standards.

What is sustainable aviation fuel?

Sustainable aviation fuel is a fuel derived from renewable resources, known as feedstocks. While traditional jet fuel is made from fossil fuels extracted from the earth, SAF utilizes more sustainable materials and is produced through various conversion technologies called processing pathways.

Additionally, SAF is blended with conventional jet fuel and used as a drop-in substitute, compatible with today’s aircraft engines without modifications—making it an immediately available solution for use.

What makes SAF "sustainable?"

To be considered sustainable, it must meet criteria, including:

- Production without depleting natural resources (limited fresh water requirements, no competition with food crops, and avoidance of environmental challenges like as deforestation, soil productivity loss, or biodiversity loss)

- Use of alternative materials instead of crude oil

- Demonstrate a net carbon reduction through lifecycle analysis (LCA)

Both the feedstock and processing pathway impact SAF’s emissions footprint. Based on these variables, SAF has the potential to reduce lifecycle carbon emissions by up to 80%, making it a significantly more sustainable, low-carbon alternative to fossil-based fuel.

What are feedstocks?

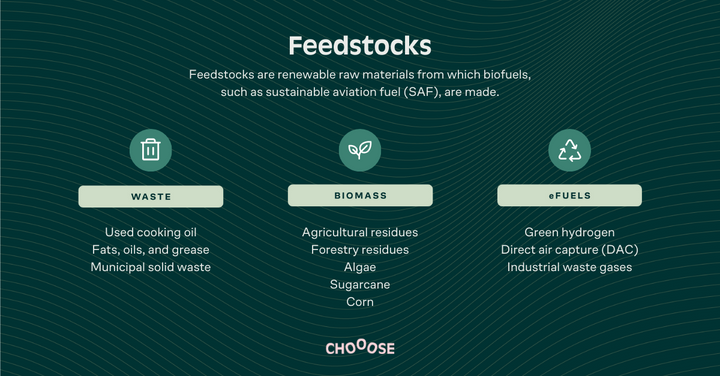

Feedstocks are raw materials used for energy conversion and biofuel production, falling into 3 main categories: waste, biomass, and carbon capture.

Examples of feedstocks include:

- Fats, oils, and greases from cooking waste and meat production

- Municipal solid waste

- Agricultural and forestry residues

Today, most commercially available SAF comes from feedstocks such as cooking oil and animal fats.

How is SAF produced?

SAF is produced using conversion technologies, referred to as processing pathways. The most common pathway is HEFA (Hydrotreated Esters and Fatty Acids), which refines oils, waste, and fats into SAF using a hydrogen-infused process. Other pathways include Fischer-Tropsch and alcohol to jet processes, which rely on catalytic chemical reactions.

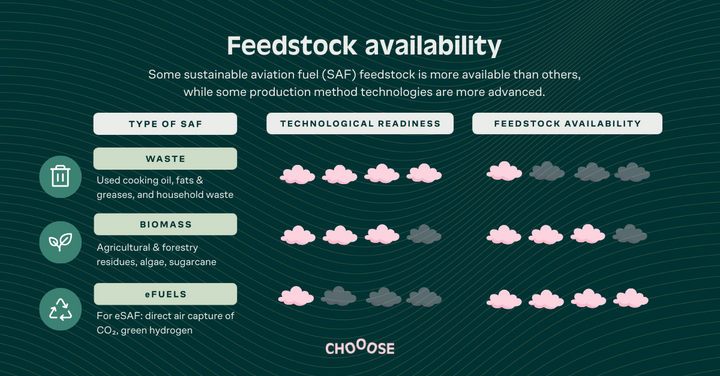

As SAF development and adoption scale, feedstocks and production technologies will evolve. For example, there is potential for eSAF, which is created by capturing carbon from the atmosphere and converting it into fuel; however, production abilities must advance before this is scalable. In the future, feedstock mix will vary, depending on the availability of the resource and its corresponding processing pathways.

SAF represents just 0.1% of global jet fuel demand from airlines—but with increased investment into its production and commercialization, SAF can scale enough to make a meaningful impact on aviation’s carbon footprint.

The SAF cycle: Reducing emissions on a lifecycle basis

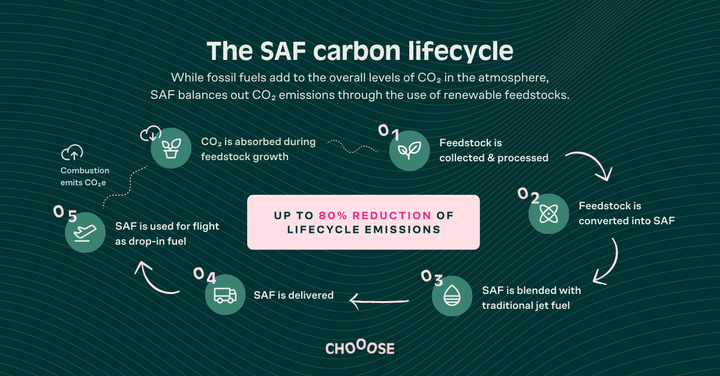

By using renewable feedstocks, SAF is able to reduce the carbon footprint associated with flying on a lifecycle basis in comparison to fossil fuels, which add to overall CO2 levels by emitting carbon that had been previously locked away.

More specifically, CO2 is absorbed by plants during the growth of biomass, which roughly equates to the amount of carbon dioxide generated when fuel is burned in a combustion engine and returned to the atmosphere. Even when emissions released during the production of SAF are accounted for—from equipment required to grow crops, transport the raw goods, and refine the fuel—SAF is still able to provide significant CO2 lifecycle emissions reductions compared to traditional jet fuel.

As the aviation industry navigates towards a more sustainable future, the intricacies of SAF feedstock resourcing, production processes, and reduction of emissions on a lifecycle basis have a collective role to play in the decarbonization of aviation. As the solution with the most opportunity to make an impact on carbon emissions, it is crucial for stakeholders in the industry to champion the use of SAF over years to come.

Reach out to CHOOOSE to learn how to leverage the benefits of SAF via a carbon program.

—

Sources: IATA (1) (2) (3), World Economic Forum (1), ICAO (1)

POLICIES

PRODUCT